High requirements

Are you looking for high-quality plastic parts that are built to last? We specialize in producing top-of-the-line plastic parts with the primarily focus on the manufacturing industry.

It is very common for our products to have high requirements for dimensional accuracy, finish, aging stability, and shape stability.

We have both vertical- and horizontal machines, many with robot cells especially adjusted for injection moulding.

The locking force of our machines ranges from 35 to 350 tons and we have the ability to produce plastic parts ranging from ~1 to 1000g. Our robot cells, and their programs, are designed and maintained by us at site.

Cost effective & flexible

Our machine park with multiple robot stations makes our operations efficient and flexible. This gives us the ability to quickly switch between jobs.

With our extensive knowledge in the plastics industry, we can provide you with expert advice on which raw materials to chose for your needs. Rest assured that we will always provide the most cost-effective options with the best durability.

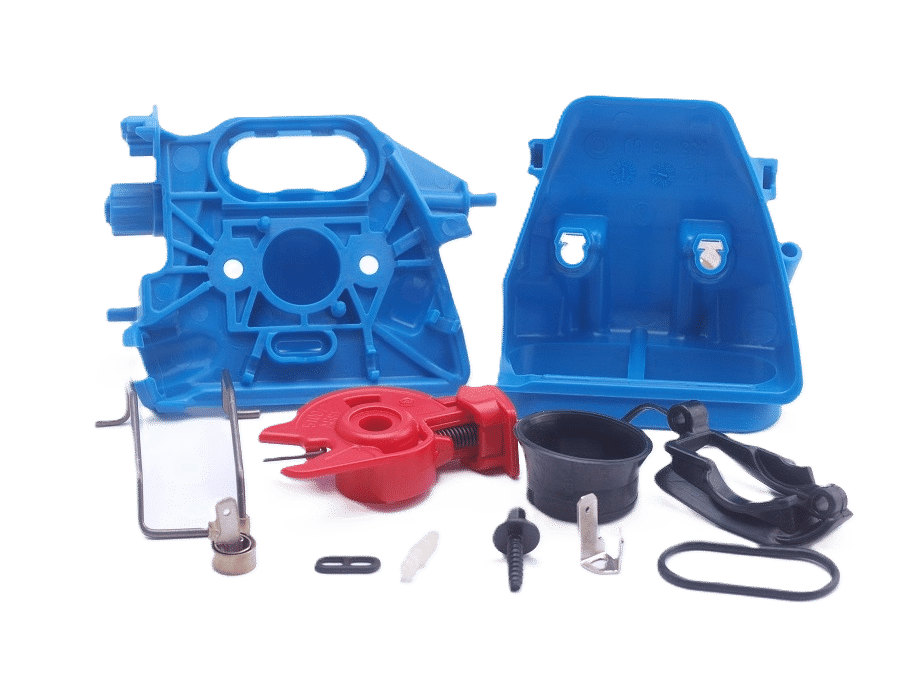

A prime example is our 2 component starter housing – manufactured for Husqvarna AB. We always strive to create a great user- and customer experience.

Injection moulding

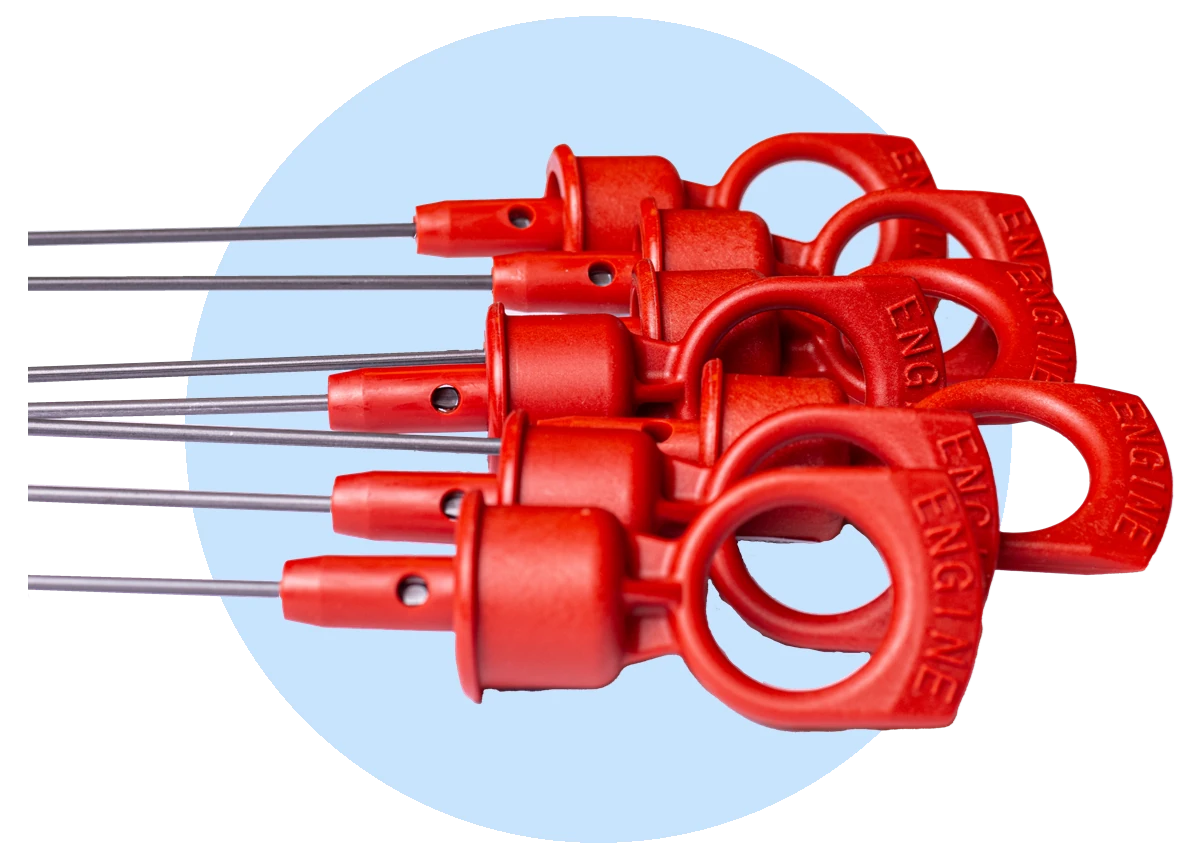

We have extensive experience in injection moulding various types of filter materials. This gives us the ability to injection mould filters in different types of plastic parts and components.

When developing a new product, we are happy to advise our customers on the most suitable process.

For example, a bushing is often injection moulded to reinforce the plastic during screwing. This can also be applied to examples such as plates, shafts, screws and nuts.

Assembly

We currently assemble multiple components for our customers. We custom-build assembly solutions to further streamline the process, where as many steps as possible are done during injection molding.

After manufacturing the plastic component, it is cost-effective to let us handle the assembly.

We provide complete system deliveries where we are responsible for everything from purchasing components to delivery to the distributor.

Contact us

Our expertise has made us a trusted partner to more than 80 customers in over 100 countries since our establishment in 1965. With our experience in the industry, we provide complete product development and support – from design to product delivery.