Revolutionizing the industry

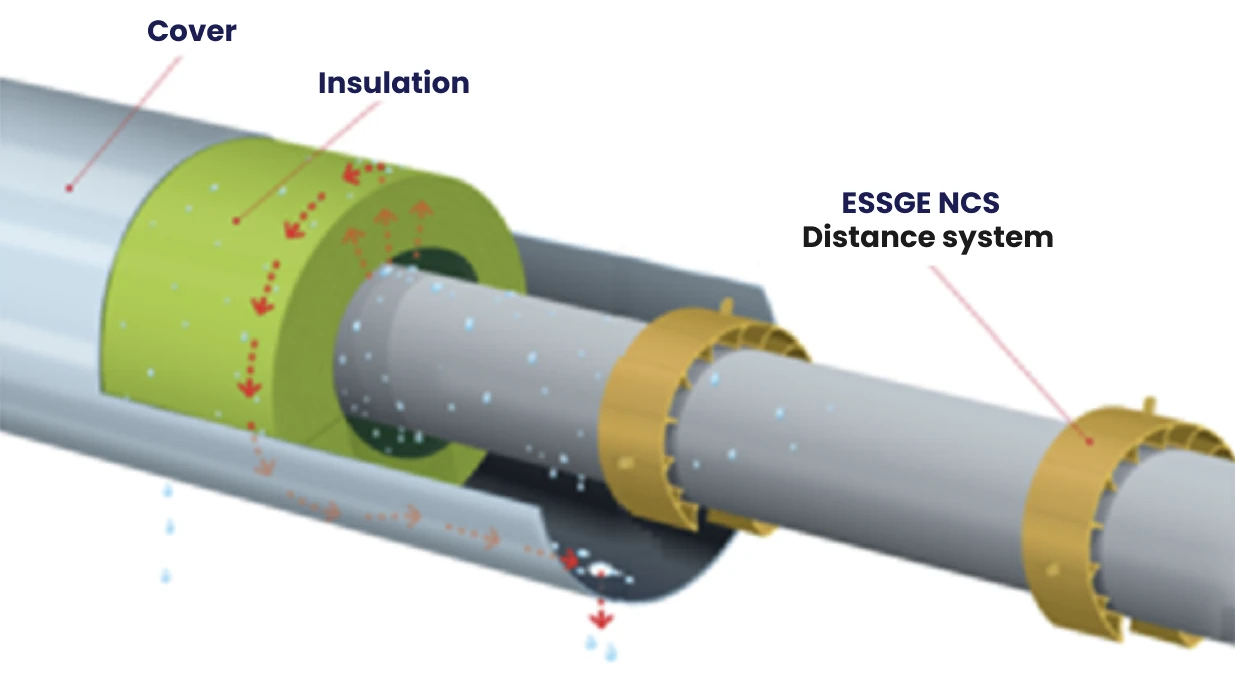

ESSGE NCS (Non Contact Insulation System) is a reliable, tested, and very quickly assembled distance system.

The unique design of ESSGE NCS ensures a contact-free insulation of pipeline systems that effectively reduces the problem of corrosion under insulation (CUI).

Unique design

The unique design of the distance system allows for easy maintenance of pipelines, without any need of tools.

The distance system, made of high-temperature resistant polymer, can be mounted without the risk of damaging coatings, paint, and any heat-increasing cables.

One of the industries most efficient solution to combat corrosion under insulation (CUI)

Download the PDF-file now to view the technical specifications and sizes.

Fast, flexible and reliable

ESSGE NCS is reliable for preventing CUI and comes in a variaty of different sizes. It’s very fast and effortless to mount.

What is corrosion under insulation?

Corrosion under insulation (CUI) is a major hazard in both on- and off-shore installations

Pipeline systems that operate at high temperatures are typically insulated to prevent heat and energy losses, as well as for health and safety reasons. Problems with corrosion under insulation can occur on carbon steel, stainless steel, and cast iron as a result of water penetrating and saturating the insulation on the pipeline system, which quickly leads to corrosion.

The annual costs of CUI is estimated to 276 billion USD [1] and is the most common cause of unplanned and costly shutdowns. Between 40% and 60% of maintenance costs for pipeline systems are related to CUI [2].

The effectiveness of distance between the pipe and insulation has been tested and recommended in the Norwegian oil and gas sector to extend the lifespan of pipeline installations [3][4].

[1] Koch, G. H., Brongers, M. P., Thompson, N. G., Virmani, Y. P., & Payer, J. H.

(2002). “Corrosion cost and preventive strategies in the United States” (No. FHWA-RD-01-156).

[2] B.

J Fitzgerald, S. Winnik, “A strategy for Preventing Corrosion Under Insulation on Pipeline in the Petrochemical Industry”, JPCL, April 2005.ä

[3] Haraldsen, K.: ”

Corrosion under insulation –testing of protective coating systems at high temperature”, Paper no 10022, NACE Corrosion 2010.

[4] Kvilhaug F.A.: “

How do different insulation solutions affect corrosion under isolation (CUI)?” Bergen, Norway, Overflate 2014

Bigger needs? Don’t worry.

ESSGE NCS Band is the solution for CUI-reducing insulation on large pipes, tanks and towers, with reduced risk of damaging coatings, paint, and heat-tracing cables.

It consists of distance elements, moulded onto an AISI 316L stainless steel band, to prevent CUI between the insulation and the object.

Highly customizable

Effortless assembly, thanks to pre-formed holes and slots used with stainless steel rivets for joints and fastenings.

ESSGE NCS Band is normally supplied in 10-meter rolls but can be manufactured in special lengths.

Contact us

Our expertise has made us a trusted partner to more than 80 customers in over 100 countries since our establishment in 1965. With our experience in the industry, we provide complete product development and support – from design to product delivery.